Today’s

manufacturing industries worldwide are facing several

challenges such as shorter product life cycles, frequent design

revisions, stringent demands on product quality and need for

shortest time to market. Product development activities have

become customer centric rather than manufacturer driven.

Globalization has added a new dimension to this scenario making

manufacturers to look for solutions to tap physical and

knowledge resources distributed across the globe.

During the past five years,

the internet has emerged as a powerful tool to enable integration

of distributed data

to provide

collaboration and interoperability. However as of now,

internet applications are mostly developed for e-commerce,

facilitating communication in the form of transmission of

data,

pictures and videos. Realizing the potential of Internet,

researchers worldwide are attempting to develop network centric

CAD/CAM applications for global product development.

WebNC is an internet based

product design and manufacturing system indigenously developed

by Prof S S Pande

and his team at Computer Aided Manufacturing Lab,

Department of Mechanical Engineering, IIT Bombay.

About WebNC

WebNC is an internet based software for feature based product

modeling and intelligent process planning to manufacture

prismatic parts on 3 axis CNC machining centres. It caters

to

part shapes commonly occurring in automobile, aerospace,

consumer goods and electric part manufacturing industries.

Due to its Client - Server architecture, WebNC can enable

integration of globally distributed product designers,

process

planners and remote CNC machines for collaborative product

development and telemanufacturing. In addition it is

an

excellent didactic tool for education, training and virtual

product development.

Fig. 1 shows the modular architecture of webNC

system. It primarily comprises of four functional modules:

communication, feature based modeler, intelligent process

planning and CNC simulator.

Communication module establishes 'Anywhere

Anytime' connectivity between globally distributed users

clients) and CNC machines. Working on Thin Client - Thick

Server architecture, it handles issues like user authentication,

transfer and collaboration with remote site CNC

machines for telemanufacturing. Fig. 2 shows the User

Interface of webNC.

Feature Based Modeler (FBMod) provides a very

user friendly graphical part modeling environment to create

solid

models of parts using design by features philosophy. A

rich library of part feature families such as holes, pockets,

slots, steps, array patterns and complex features

like freeform surfaces,

compound types, derived from actual industrial parts

has been provided. Users can easily synthesize/edit/visualize

CAD part models using the feature library provided.

Intelligent checks have

been provided in FBMod for automatic validation of CAD models

based on design for manufacture

(DFM) strategy. Users can dynamically view the CAD

models during design session using Virtual Reality (VRML)

tools. Fig. 3 shows a typical design session in progress.

Intelligent Process Planning (webCAPP) module

automatically generates efficient, error free CNC code from

the

feature based CAD model by performing four functional tasks.

These are automated multi-setup planning, intelligent operation

sequencing using genetic algorithms, automatic tool and

process parameters selection and set up wise CNC program

generation. The CNC code is post processed to FANUC and

neutral data formats to enable running it on any industrial

CNC machine. A customizable tool database has also been

provided to suit industrial shop conditions if desired.

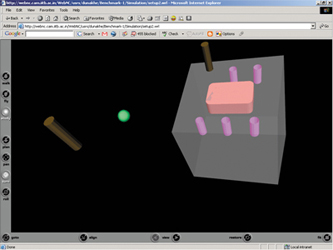

CNC simulator (webSIM) provides the user

with a

virtual CNC machining environment to graphically simulate

the CNC code before running it on the machine. Fig. 4 shows

typical web based CNC Simulation in progress.

Product Testing

WebNC has been extensively tested from various locations

in

India and abroad on typical parts taken from actual

industrial

shops. Part programs generated by webNC were used

to

cut components on CNC machines. webNC was found to

generate optimum, error free CNC part programs consistently.

A PC with net connection is sufficient to use webNC.

No proprietary CAD/CAM software is required at the

user

end. This software is available for commercial use

by the

industries and educational institutes.

Contact: s.s.pande@iitb.ac.in

Visit: www.me.iitb.ac.in/~sspande/