An

Indian Patent titled "A compact drive mechanism of a

reciprocating machine" was granted to IIT Bombay on 5

June

2006. According to the inventor, Prof S L Bapat, Department

of Mechanical Engineering, the objective of the invention is

to

provide a compact and efficient drive mechanism for a reciprocating

machine that is free from side thrust.

The utility of this drive mechanism ranges from reciprocating

compressor and pump (also vacuum pump) to stirling

cycle machines (coolers as well as engines), internal combustion

engines and pulse tube cryocoolers. The drive mechanism

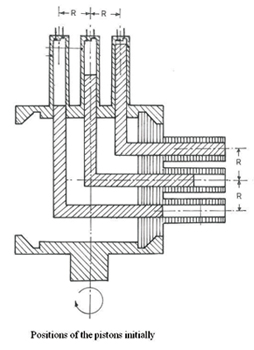

consists of two horizontal circular discs parallel to each

other, both having a coinciding circumferential groove of

same size and shape. One of these discs is stationary while

the

An

Indian Patent titled "A compact drive mechanism of a

reciprocating machine" was granted to IIT Bombay on 5

June

2006. According to the inventor, Prof S L Bapat, Department

of Mechanical Engineering, the objective of the invention is

to

provide a compact and efficient drive mechanism for a reciprocating

machine that is free from side thrust.

The utility of this drive mechanism ranges from reciprocating

compressor and pump (also vacuum pump) to stirling

cycle machines (coolers as well as engines), internal combustion

engines and pulse tube cryocoolers. The drive mechanism

consists of two horizontal circular discs parallel to each

other, both having a coinciding circumferential groove of

same size and shape. One of these discs is stationary while

the

other (driving disc) is rotated using a prime mover. A vertical

(driven) disc with external surface matching the curvature

of

the grooves is placed in between

the two horizontal plates. It

rotates in the grooves about the

central axis of the mechanism

and also about its own horizontal

axis, which ends up in a planetary

motion. This vertical disc

has equally spaced circular

holes, with same pitch circle

diameter through it.

Similarly, the horizontal

stationary disc has same number

of holes to hold tubes acting as

cylinders. Two circular rods are

coupled to each other at right

angle to obtain a L-shaped member.

The horizontal limbs of such

L-shaped members are inserted

through holes in the vertical disc

and the guide sleeve where they

rotate and reciprocate and act as

load bearing limbs. The vertical

limbs act as pistons and reciprocate (and simultaneously

rotate) in the respective cylinders mounted on horizontal stationary

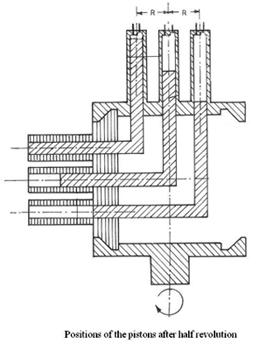

disc. One rotation of the vertical disc is equivalent to

two strokes (one upward and one downward) of each piston.

Thus, the rotary motion is converted to reciprocating one

using this compact drive mechanism. The drive mechanism

enable it to have large stroke to diameter ratio. Moreover,

the

orientation of the drive mechanism has no effect on the performance

of the application for which it is used. The line contact

between the mating members ensures least frictional loss.

The number of piston-cylinder combinations and angular

phase difference between them can be adjusted within the

geometrical constraints.

Contact: slbapat@iitb.ac.in.