Multi-Utility

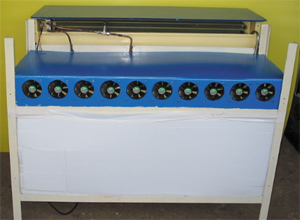

Heat Pumps is based on patented technology

which will help reduce cost of pre-cooling milk, fruits and

vegetables while simultaneously drying fruits, herbs or spices.

Heat required for low temperature drying is delivered free

of

cost, while simultaneously increasing the cooling capacity

and

coefficient of performance of the refrigeration system.

Waste

heat from refrigeration units of milk chillers, cold stores

and fruit pre-coolers can be recovered

using novel patented Tube-Tube Heat Exchangers.

These vented double wall tube and tube heat exchangers

(Indian Patent # 205 362) enable recovery of the waste

heat in a reliable and cost effective manner.

This recovered

heat, in the form of hot water at 45 to 600 C can then be

used in plastic heat exchangers

to dry various products. Hot utility can be used to dry

agro products to generate additional revenue.

Plastic Solar Dryers are based on patent

pending

technology wherein, light weight plastic collectors generate

hot air to dry fruits, vegetables, herbs or spices.

Hot air required for low temperature drying is circulated

using PV operated fan for off-grid applications. Grapes,

tomatoes, onion, guava, can be dried with the hot air,

with out exposure to direct sunlight. Low temperature

drying usually results in better quality products resulting

in

higher value realization.

Benefits

Benefits

The heat pumps can be used for on-farm pre-cooling of

fresh

fruits like guava or grapes, while simultaneously drying

guava

paste or grapes. Pre-cooling is said to increase shelf

life by a

factor of three, thereby reducing the loss during storage,

transport and retail sale.

Distress sale of harvested perishable produce can be

avoided with the help of pre-cooling or cold store

facility.

Economics of pre-cooling and cold store operation will

improve

significantly due to additional revenue generated from

drying.

Limited availability of electric power and unpredictability

of

power cuts can be factored in by incorporating low

cost ice

bank tank (IBT) or chilled/hot water storage tank/s.

Techno-Economic Viability

The technology of the heat pumps has been tested for

industrial,

commercial and residential applications. Suitable

modifications

will be undertaken to meet the needs of the rural

applications.

Payback period of 0.5 to 1 year is possible for such

grid

connected robust heat pumps for the rural market.

Plastic Solar Dryers based on novel light-weight

highefficiency

Plastic Solar Air Heaters costing about Rs 5000 to

6000/m2 aperture area can be coupled to efficiently

heat

ambient air to 50 to 900 C for use in dryers. Air

in these lowpressure

drop solar air heaters is circulated using PV driven

fans of 5 to 10 W. These solar dryer can be used

effectively

used in off-grid locations. Expected payback for

drying various

agro produce like onions, grapes, ginger, herbs is

in the

range of 1 to 1.5 years.

There are several lucrative opportunities

to benefit from heat pump and solar dryer technologies in our

country.

Based on survey at the Rahata Block in Maharashtra,

INDIA,

these systems could be used for milk chilling,

pre-cooling

guava and grapes; while drying grapes, onion, guava

paste,

herbs and spices.

Contact: ranemv@iitb.ac.in